What does the Fourth Industrial Revolution mean for our jobs?

Image: An employee monitors an automated substance library at the Pharma Research Center of Bayer HealthCare in Wuppertal February 24, 2014. Bayer AG will announce its 2013 report at an annual news conference on Friday. Picture taken on February 24, 2014. REUTERS/Ina Fassbender

What does the Industrial Internet of Things (IIoT) mean to me? Well, to put it simply: a job with a future.

I am a content creator for an Industrial Apps provider.

I am a millennial. When companies like AOL first arrived on the scene, I was just a boy.

Growing up in the 90’s, I got used to adapting to rapidly advancing technology. I listened to my first few favourite bands on cassette, then I moved on to CDs, then mp3, and now I listen to my favourite music from my smartphone which has a wireless connection to my Bluetooth speakers.

I still shake my head whenever my grandfather fires up his 8-track player.

A global community within the industrial sector

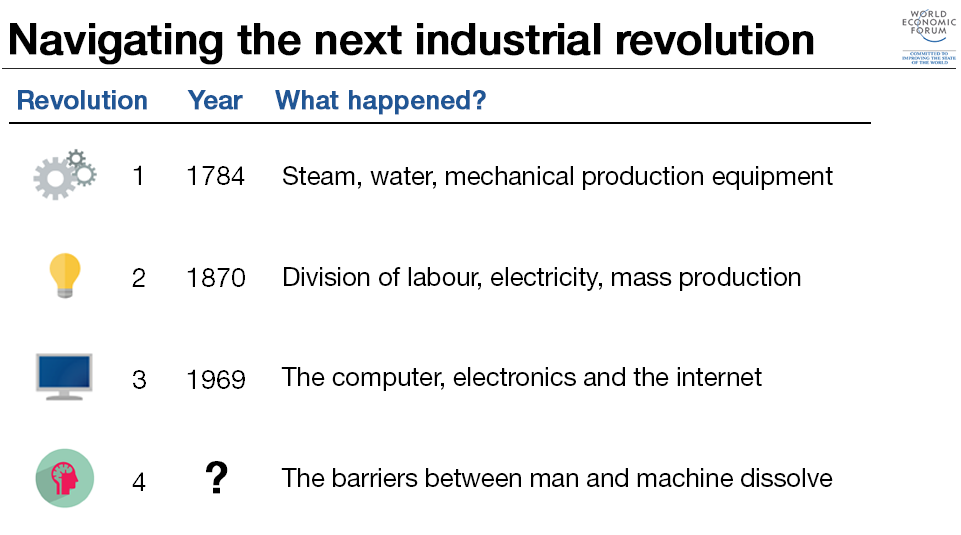

The IIoT has been labeled the Fourth Industrial Revolution and it is not merely revolutionary for end-users; it’s revolutionary for software providers as well. The IIoT is allowing companies (and employees) in non-traditional markets to thrive on a global scale.

Thanks to the opportunities created by the IIoT, I was able to move back to Moncton (a small city on Canada’s east coast) from a larger Canadian metropolis, and work in a rapidly growing industry as part of RtTech Software’s team, right here, in my home town.

RtTech Software has been able to branch out from a small market and reach a global client base which spans across 15 countries. Prior to the IIoT, a software company like RtTech could never have thrived in a non-traditional market due to logistical reasons.

Headquartered in little ol’ Moncton, RtTech’s Industrial Analytic Apps monitor and track production data and provide real-time data analytics to help manufacturing companies avoid lost productivity and decrease energy consumption.

Since I am in the infancy of my professional career, what I see that excites me about the IIoT is its future. The possibilities in the industrial manufacturing sector appear to be nearly limitless.

New trend: companies working smarter rather than harder

Putting a little extra “elbow grease” into your work isn’t necessarily a good thing anymore (and with that, all couch potatoes rejoice). Mundane tasks are being replaced by more significant and engaging work for employees as Smart Technology is allowing for increased worker productivity by having computers do the tedious and time consuming work (sorry lazy people, you still have to actually do some work).

Smart Technology is empowering the workforce. With IIoT solutions, employees develop working relationships with intelligent machines to achieve production results that neither human nor machine could accomplish independently.

As IIoT innovations continue to develop, it is expected that the number of connected devices will multiply into the tens of billions. Many industrial organizations already see considerable value in IIoT technology as a complementary service to Big Data analytics. Accenture estimates that the IIoT will add $10 trillion to the global economy by 2030. That sounds like a lot of future jobs for millennials like myself.

I hope to see continued growth in government support and grants, not only in technological studies and development, but also in funding for businesses to implement technology (such as IIoT solutions) in their organizations. Government funding is often crucial in helping companies invest in new technology.

Breaking down barriers

Seeing the need for more cost-effective solutions, with faster ROI, many software solutions are now becoming available as cloud-based solutions, which is fueling the Fourth Industrial Revolution.

Before the IIoT, software solutions were fairly one dimensional; available only in an on-premise format. With on-premise solutions came all of the benefits of Big Data analytics but with an often-times large, upfront price tag.

Therefore, without the IIoT, industrial software technology served only large organizations with the financial flexibility within their budgets to allow for a significant upfront expense in order to benefit from the use of these solutions. I guess it takes money to save money with software solutions. Seems a little problematic for the little-guy, right?

The implementation of cloud technology in the industrial software industry has allowed for solution providers to offer more cost effective solutions as an affordable, monthly subscription, rather than a large, upfront investment.

Cloud-based solutions have allowed small-to-medium sized manufacturers to level the playing field with their larger competitors. Having access to innovative analytic software on a monthly subscription format, allows for these small-to-medium sized manufacturers to benefit from the same technology that was once a much more expensive investment.

It is this same principle which allows for software providers (like RtTech) to thrive in non-traditional markets. With cloud technology, software providers are able to remotely monitor their installations. This capability has broken down a barrier, creating a truly global community through the power of the internet and connected devices.

The best is yet to come

One thing to remember with IIoT solutions is that they are ultimately tools to assist with production. The solutions we are seeing emerge in today’s manufacturing and production industries are meant to empower the workforce and improve operating systems.

The success of IIoT innovations and the industry as a whole will come down to one, major factor: human integration. Will we fully embrace this new technology at our disposal and use it to our advantage?

The next few years will be vital to the development of the IIoT. The Fourth Industrial Revolution has taken us on a whirlwind of a ride thus far. But fasten your seat-belt, because there’s only more excitement to come.

I look forward to seeing what the IIoT has in store for us, and also, what we have in store for it.

This article was first published on Medium, as part of the World Economic Forum’s essay contest for Davos 2016. The shortlist will be announced later this week.

Author: Brett Lewis, Digital Content Specialist at RtTech Software.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Fourth Industrial Revolution

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Technological InnovationSee all

Jason Szolomayer and Alice Hawamleh

December 8, 2025