How Italian brands can improve the sustainability of their supply chains

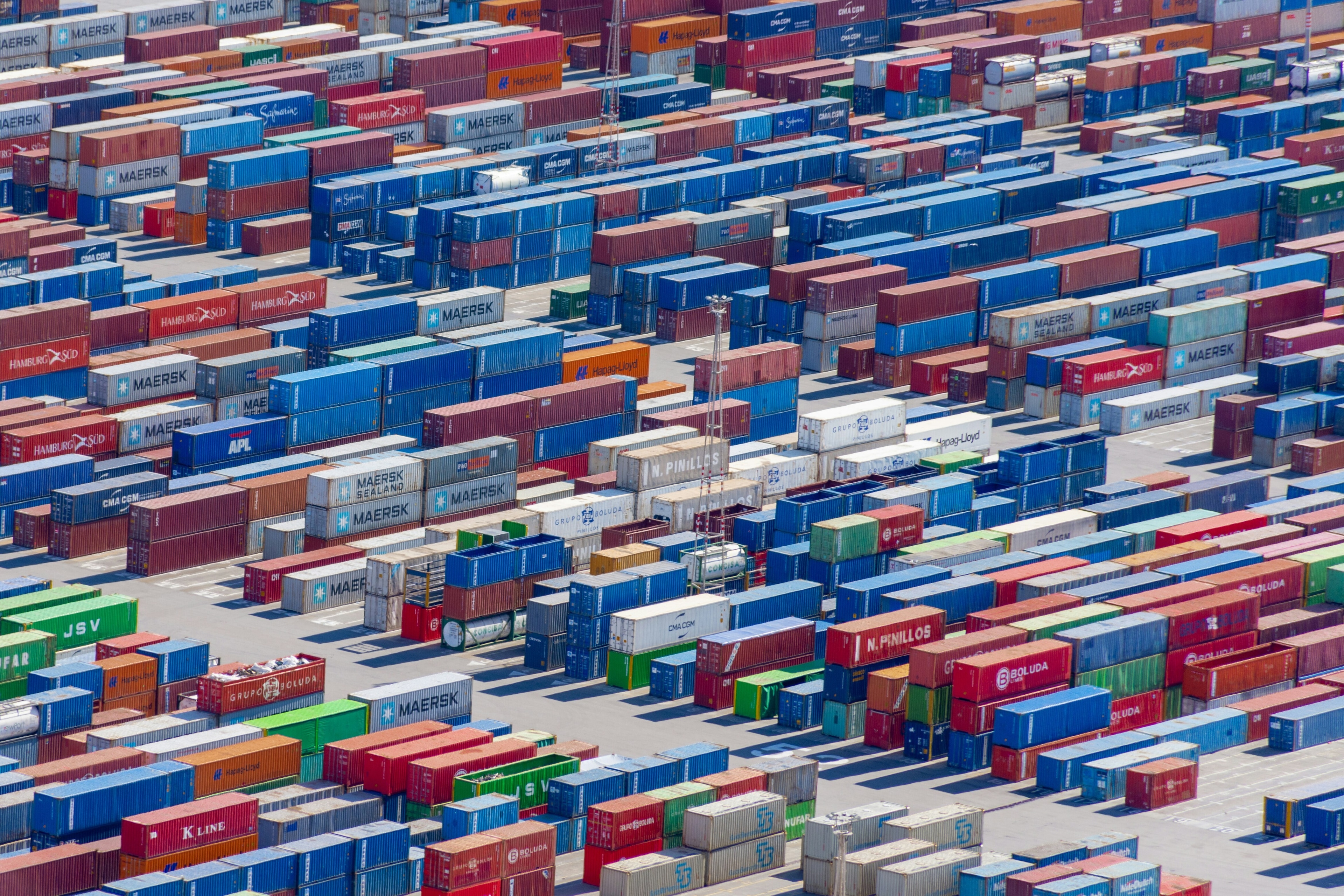

Despite Italy’s GDP drop of almost 9% last year, its top 30 labels managed to increase their value by 11%. Image: Unsplash

Listen to the article

- 'Made in Italy’s' reputation for authenticity and quality has made it a powerful tool for exports.

- However, the supply chain for products may be almost completely outsourced and reliant on foreign labour.

- Although significant improvements in social sustainability are expected in the next few years, more can be done to improve transparency, monitoring and accountability.

You read 'Made in Italy' and immediately think of an old artisan, slowly sewing in a family-owned atelier. You read 'Made in Bangladesh' and perhaps you picture women and children being exploited in some dimly lit and unsafe warehouse. While the first is associated with high-end products, the second (justly) spurs talk of human rights. The reality is that these two pictures are pieces of the same puzzle.

Few labels have a stronger association with luxurious handcraft than Made in Italy. Made in Italy’s connection with traditional authenticity and refined quality has always been a powerful export product that withstood trends and fluctuations in the wider economy, and COVID-19 was no exception.

Despite Italy’s GDP drop of almost 9% last year and the 15% loss of worth of its national brand, its top 30 labels managed to increase their value by 11%, reaching a total value of US$114.6 billion. Confirming the findings of previous reports, the Kantar BrandZ 2021 ranking found that the biggest contributor to that figure is the luxury sector. Out of the 30 top national brands, the seven that belong to the fashion industry account for 42% of the total worth. Besides Gucci, the best-performing brand in Italy, Prada and Fendi are within the top 10 and Bottega Veneta credited itself as one of the fastest risers of the year.

The dependence of fashion on seasonal trends and the reliance of luxury on outstanding quality both hinder the industry’s standardization and increase the importance of the people that manually make the high-end products. Often regarded more as artists than factory workers, those people pique the interest of the rest of the world for what they make, but what about how they make it?

Let's start with geography.

Where is Made in Italy really made?

Not necessarily in Italy, unlike '100% Made in Italy', which is a certification issued by the Institute for the Protection of Italian Manufacturers that demands that products be:

- Designed and manufactured entirely in Italy

- Made with quality natural materials

- Made following traditional working methods

- Made in observance of employee, health and safety standards

Made in Italy is a thin label. For a product to be Made in Italy, it needs to have received a “substantial and economically justified” final “transformation” on Italian soil. This means that the supply chain may almost completely be outsourced and reliant on a foreign workforce. Once this meant China, but today it is more often countries like Bangladesh, Viet Nam and Indonesia that receive these textile orders and keep Italian brands competitive. This is of course misleading for consumers who are unaware of the importance of that missing '100%', and also because it increases the chances of workers being poorly treated.

How is Made in Italy really made?

The truth is we often don’t know, and that’s down to a lack of transparency, accountability, monitoring, or both.

Fashion Revolution reports in its 2020 Transparency Index that less than a quarter (23%) of brands disclose their company's approach to paying a living wage to workers in their supply chain, and only five brands out of the researched 250 (2%) publish a time-bound, measurable roadmap or strategy for how they will achieve a living wage (often way higher than the national minimum wage, as reported by Clean Clothes Campaign) for all workers across their supply chains. Meanwhile, only five brands publish data on the percentage above the minimum wage rate workers are paid in their supply chains.

Lack of transparency also brings with it a lack of accountability. The so-called “corporate veil” (when companies act through subsidiaries) allows unfair corporate practices to go unnoticed or unpunished. The absence of a binding international law on human rights leaves room for abuses of national laws, which is what makes the incoming mandatory human rights and environmental due diligence directive (“mHRDD”) of the European Union so groundbreaking. For the first time companies will be held responsible for their entire chain, even if it crosses borders and goes through different contractors.

But although significant improvements in social sustainability are expected in the next few years, a well-functioning legal framework that allows for proper sanctioning and regulation is not enough.

More needs to be done on the auditing and monitoring side, as Marina Spadafora, Fashion Revolution Italia, and Deborah Lucchetti, Clean Clothes Campaign Italia, said in a recent interview. After big scandals, most companies are quick in drawing declarations of intent, but nobody is as quick in following up on those declarations and monitoring the impact that new corporate policies have on workers.

Certifications that grant environmental and social standards already do exist, and often require some auditing activities from external parties, but they respond to basic corporate compliance and present all the issues that come with certifications. The Institute for Multi-Stakeholder Initiative Integrity (MSI Integrity) drafted a report in July 2020, assessing whether MSIs delivered on their promise to protect human rights. The answer was no, as they “are not effective tools for holding corporations accountable for abuses, protecting rights holders against human rights violations, or providing survivors and victims with access to remedy.” In other words, they are not fit for purpose, whether the production is in developing or developed countries.

The textile sector in Italy, as highlighted by the Social Sustainability Roadmap of the Fair Wage pilot project, is the second major industry in the country and it employs more than 500,000 people and includes large luxury brands and small businesses, family-owned or otherwise. According to the 2019/2020 survey carried out by Camera Nazionale della Moda Italiana on the working conditions and wages of the thousands of people employed (legally) by the fashion luxury sector, we know that:

• In terms of legal compliance, living wage remuneration, trade union representation, dynamic wage developments and professional growth, the fashion industry is well positioned;

• Further improvement could be made in monitoring differences in living standards, making pay systems fairer and more performant.

There is also an ethical certification, granted by the Institute for the Protection of Italian Manufacturers, that aims to add to the trustworthiness of the '100% Made in Italy' brand. Given to certain companies that produce entirely in Italy, the certification recognizes their respect for the consumers, the employees and collaborators and the environment.

But.

The truth is that 100% Made in Italy is not as strong a brand as its more international sister, which implies that many brands that actually are entirely Made in Italy are not certified and do not figure among the certified list. Showing that '100%' means too little to consumers as they don’t know the difference. As Deborah Lucchetti commented, there isn’t really much in Italy to foster a transparent, accountable and monitored fashion production system.

Made in Italy is as socially sustainable as any other 'Made-in'. The chances of it suffering from a lack of transparency, accountability and monitoring are as high as they are anywhere else, at least until the new European mHRDD is properly in place. One-hundred percent Made in Italy could be a safer bet, but as long as it’s not properly recognized and sought after, it will remain a good idea, but one for another time.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Italy

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Manufacturing and Value ChainsSee all

Caroline Narich, Maria De Miguel, Jessika E. Trancik and Christine Gschwendtner

November 12, 2025