3 reasons why decarbonising industry might be easier than thought

Industry must decarbonise fast for the sake of the planet

Image: Photo by Patrick Hendry on Unsplash

Stay up to date:

SDG 09: Industry, Innovation and Infrastructure

Listen to the article

- Industry is the single biggest driver of climate change, accounting for nearly a third of global emissions.

- If we can’t decarbonise industry, we can’t meet our climate goals.

- But industry has a formula with the potential to knock out more than half of industrial emissions: renewable electricity + thermal energy storage.

Industry is the single biggest driver of climate change, accounting for nearly a third of global emissions. This fact underlines a harsh reality: if we can’t decarbonise industry, we can’t meet our climate goals.

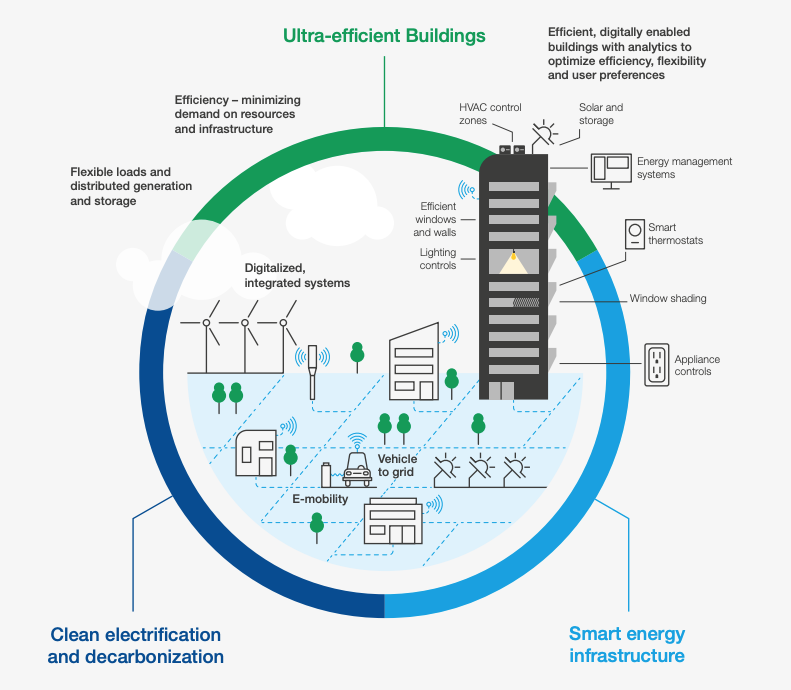

While every sector faces challenges to decarbonise, most have a straightforward formula to do so. For the electricity grid, it’s cheap wind and solar coupled with round-the-clock energy storage. For buildings, it’s electrification and efficiency. For ground transportation, it’s electric vehicles and charging networks.

Industry, meanwhile, has been dubbed “hard-to-decarbonise.” But industry has a straightforward formula of its own, with the potential to knock out more than half of industrial emissions: renewable electricity + thermal energy storage.

What is the Forum doing to help cities to reach a net-zero carbon future?

The industrial heat opportunity

Nearly every industrial facility relies on heat to melt, dry, cook, separate, calcine or otherwise transform materials. This heat accounts for two-thirds of all industrial energy use and the majority of all industrial emissions.

Situated within an incredibly complex sector, most industrial heat is extraordinarily simple: to make just about anything, manufacturers burn fossil fuels to deliver steam or hot air to the manufacturing process through a pipe.

If we can solve the challenge of clean industrial heat, we can pave a new path to rapid industrial decarbonisation.

Thermal energy storage, powered by renewable energy, will decarbonise industrial heat.

It’s not by chance that nearly every industrial facility relies on fossil fuels to produce heat. Fossil fuels are cheap, easily stored and easily delivered as heat to industrial processes. To date, it’s been difficult for alternatives to compete with fossil fuels on all three aspects.

But that is changing. Here are three reasons why decarbonising industry can be faster and simpler than many have thought possible:

1. Cheap renewable energy opens a massive opportunity for industrial decarbonisation

From induction heaters to electric arc furnaces, electricity is used extensively in industrial facilities due to its simplicity and ability to achieve much higher temperatures than burning fossil fuels. But using round-the-clock grid electricity to produce industrial heat is often five times more expensive than burning fossil fuels onsite. Over the last decade, however, the cost of renewables has declined dramatically, making wind and solar the cheapest sources of new electricity nearly everywhere on the planet.

The recent explosion of renewable resources changes the picture on electricity cost: when the sun is shining or the wind is blowing, the cost of electricity dips towards zero and can even turn negative. We’re already seeing these effects in areas with high renewable penetrations. In parts of the United States, wholesale electricity prices dropped below zero as much as 30% of the time last year.

But cheap wind and solar are not sufficient to decarbonise industrial heat. Industry requires process heat every hour of every day, delivered onsite to millions of facilities. To unlock the decarbonisation potential of cheap renewable energy, we must store it, so it can be delivered reliably around the clock.

Have you read?

G7 agrees to accelerate phase-out of unabated fossil fuels. What you need to know about the global energy transition this week

Does the potential for corruption in the mining sector threaten a just energy transition?

As generative AI gains pace, industry leaders explain how to make it a force for good

2. Thermal energy storage enables us to store this energy using low-cost, scalable and abundant materials

Thermal energy storage (TES) enables us to use renewable energy when it's least expensive — when the sun is shining or the wind is blowing — to heat up a 'thermal battery' to thousands of degrees, store that heat for hours or days and output it on-demand. A radically simple approach to energy storage, thermal batteries can be cheaply assembled, easily maintained and operated for decades.

Most importantly, thermal batteries don’t rely on the expensive, scarce materials required in most other batteries. Since thermal batteries store energy as heat, instead of electricity, they can use cheap and abundant materials, such as concrete and carbon, surrounded by a simple insulated container.

Take carbon, for example. Solid carbon, which is used by TES companies such as Antora Energy, is extremely cheap and it has a vast existing supply chain of over 30 million tons every year — more than 50 times that of lithium. Plus, it has the properties that are needed to store massive amounts of heat: it remains solid at extremely high temperatures, it’s exceedingly energy dense and it can quickly absorb and emit massive amounts of energy.

3. Thermal energy storage plugs clean energy directly into existing industrial processes

Thermal batteries are ideally suited for nearly every industrial process on Earth. Materials, such as carbon, can deliver heat at temperatures upwards of 1,500°C, hot enough to make steel and cement. Equally importantly, their high energy density allows thermal batteries to store this heat in an extremely small footprint. This small footprint enables thermal energy storage to be sited where heat is needed, while also reducing the cost and complexity of every other component that sits alongside the thermal battery, such as insulation and piping.

And, since wind and solar projects can be connected from miles away with minimal efficiency losses, thermal batteries can deliver clean electricity from the best renewable project sites — completing the trifecta of cost, storage and delivery that have made fossil fuels so dominant.

We can knock out over half of industrial emissions

Decarbonising industry will certainly be challenging. It requires applying new technologies to the production of the materials that define our world: steel, cement, glass, chemicals, food and more. And, different sectors will require different approaches to fully decarbonise, from carbon capture to materials innovation.

But these challenges shouldn’t stop us from tackling the largest and most addressable source of industrial emissions. Combining thermal energy storage with abundant renewable energy, we can deliver industrial heat using scalable and earth-abundant materials, cheaper than fossil fuels — eliminating more than half of all industrial emissions in the process.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Nature and BiodiversitySee all

Jean-Claude Burgelman and Lily Linke

May 9, 2025

Wietse Van Ransbeeck

May 7, 2025

Tom Crowfoot

May 7, 2025

Alfredo Giron

May 6, 2025

Tom Crowfoot

April 30, 2025