Industrial robots are bringing jobs back home, but not for low-skilled workers

Will reshored production tasks be taken over by robots than by human beings? Image: LSE Business Review

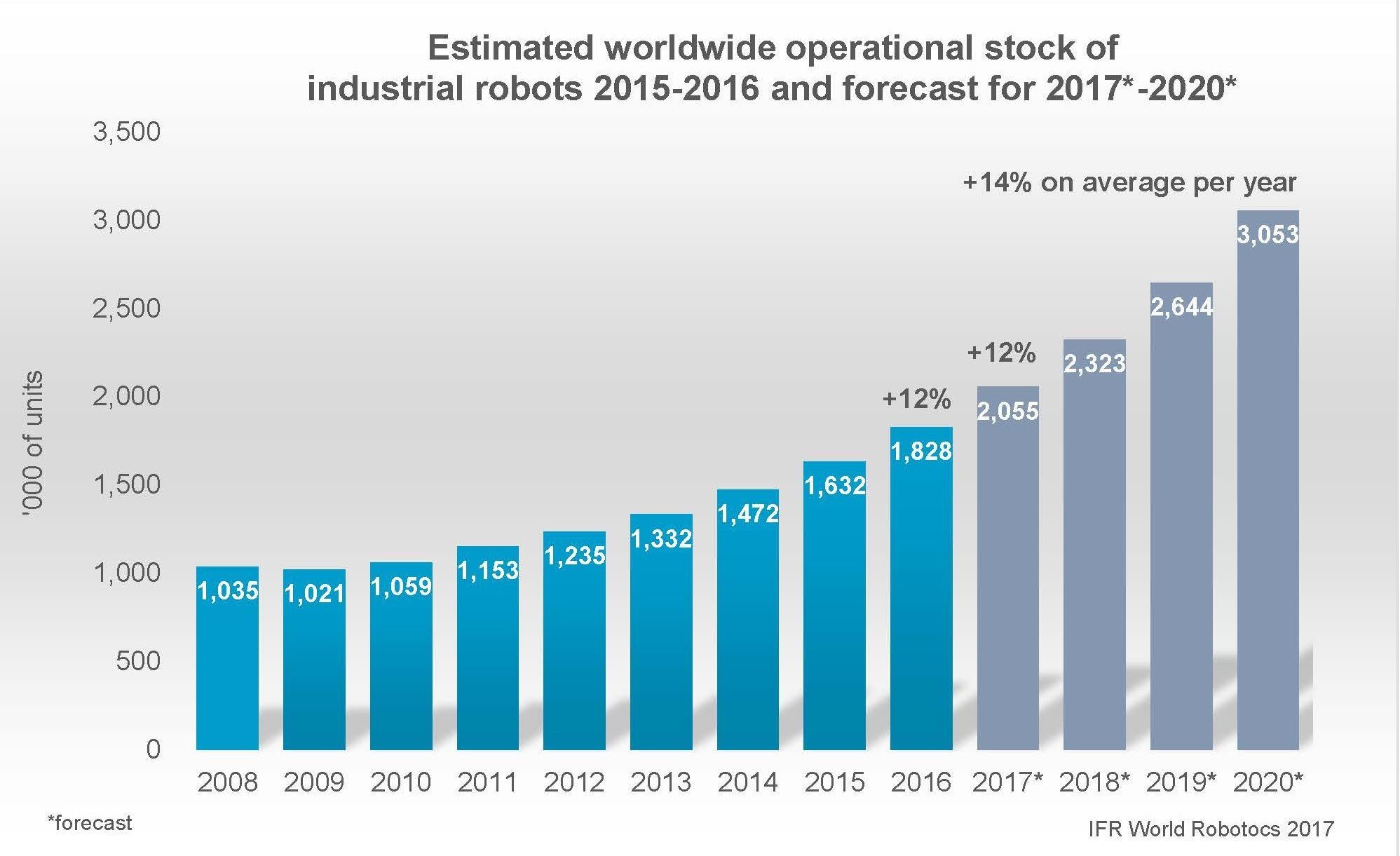

An immense rise in automation by means of industrial robots has taken place. Figures from the International Federation of Robotics reveal that while automation was almost an unkown phenomenon in the 1970s, with fewer than 3000 industrial robots installed worldwide, the operational stock of robots is nowadays already approaching 2.5 million.

At the same time, nations tend to apply more and more protectionist policies. The notion gains ground that the relocation of production from foreign countries to the home country and the renegotiation of trade deals would bring jobs back home. This argument has been most prominently expressed by Donald Trump: “Trade reform and the negotiation of great trade deals is the quickest way to bring our jobs back to our country.”

The question arises whether reshored production tasks will rather be taken over by robots than by human beings. Especially those jobs that are characterised by routine tasks and that can be easily automated (as is the case in several industry jobs) appear to be endangered. We provide an economic theory and empirical evidence for the relationship between automation, reshoring and labour market outcomes using industrial robots data from the International Federation of Robotics and production input data from the World Input Output Tables. We develop a measure of reshoring at the macroeconomic level to account for the movement of production processes from a foreign country back to the home country.

Our research reveals that increasing automation is positively associated with reshoring of production (defined as the return to the home country of production that had been previously transferred abroad, or offshored). The driving mechanism behind it is that using robots for production back in the home country becomes cheaper over time due to increasing efficiency in automation. Reshoring increases employment and wages for high-skilled but not for low-skilled workers. Inequality rises as a consequence of the increasing gap between wages for high- and lower-skilled workers.

The results show that when 1 more robot per 1000 workers is used in production, then this is associated with an increased reshoring activity of about 3.5 percent (using 1 more robot per 100 workers results in a 35 percent increase). Professional workers are better off from reshoring, whereas lower-skilled workers, those conducting routine tasks and whose jobs can be easily done by robots, do not benefit. The estimates show that on average a 10 percent increase in reshoring is associated with an annual increase of employment in the category of professional occupations by about 1150 workers, which results in an overall increase of 535,000 workers for our sample over time, but there are no effects on workers in elementary occupations.

We find a positive trend in reshoring activity from 2000 to 2014. This trend is visible way before protectionist policies came into place, but which is rather due to increasing labour costs in previous offshore destinations (Asian countries, e.g. China) and a rise in the efficiency of robots and other new technologies (which makes production by automation capital at home cheaper as compared to labour). Employers further prefer to produce back home to have a higher degree of flexibility or to better control the quality of production processes.

Have you read?

An example (see Economist, 2017) is the sports clothing producer Adidas, which has reshored production to Germany and the US from China and India; only 160 jobs were thus created compared to more than 1000 in a typical Asian factory. Robots instead of workers are now doing the knitting, cutting and additive manufacturing, etc. However, machines are not yet able to put the lace into the shoes, humans are still required to do these tasks. Aside, mostly higher-skilled workers do nowadays work in the factories, for example machine engineers.

Our study develops a new theoretical economic model, incorporating firms to produce intermediate goods either with labour at home, to offshore (using labour in the foreign country) or to reshore and using automation capital/robots at home. Firms are driven by the motivation to produce with the cheapest input factor. The model’s results show that higher protectionism (tariffs imposed on imports), higher wages in foreign countries that were previous offshore destinations and higher productivity of automation reinforce firms’ reshoring. When productivity of automation increases, more firms will reshore, given the size of tariffs (that means independently from what the size of tariffs or protectionism is). The model shows that protectionism increases the speed of reshoring, but it does not improve the lot of low-skilled workers. The model’s predictions are supported empirically by developing a novel measure for reshoring activity and applying it to macro data from Europe and the US.

Given that the use of robots is increasing at a high speed worldwide, a consequence for the future should be that employees need to be better prepared for the change in labour markets and receive higher education and training.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Education

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Education and SkillsSee all

Melonia da Gama and Natasa Perucica

November 20, 2025