New material inspired by spider silk could help solve our plastic problem

There was 340 million tonnes of plastic waste generated in 2018. Image: REUTERS/Lisa Marie David

- Packaging was responsible for 46% of plastic waste generated globally in 2018.

- The demand for food will double by 2050, increasing the amount of waste from food and its plastic packaging.

- There's a need for more sustainable materials that we can recycle or that biodegrade.

- Researchers from the University of Cambridge have found a way to make plastic from abundant and sustainable plant proteins, that looks like spider silk.

Plastics are very useful materials. They’ve contributed significant benefits to modern society. But the unprecedented amount of plastics produced over the past few decades has caused serious environmental pollution.

Packaging alone was responsible for 46% out of 340 million tonnes of plastic waste generated globally in 2018. Although plastic recycling has increased significantly in recent years, most plastics used today are single use, non-recyclable and non-biodegradable.

The demand for food will double by 2050. This will probably increase the amount of waste from food and its plastic packaging, putting poorer countries under tremendous pressure to manage waste disposal.

To tackle the issues of environmental damage, we need more sustainable materials that we can recycle or that biodegrade. There’s been a surge in plant-based plastics, but many of these can only be composted using industrial processes, not by people at home.

Now researchers at the University of Cambridge have found a way to make plastic from abundant and sustainable plant proteins. Inspired by spider silk, the film works in a way similar to other plastics, but it can be composted at home.

Types of plastic

Synthetic and non-biodegradable plastics commonly used for food packaging include polythene terephthalate (PET), polystyrene (PS) and crystalline polythene terephthalate (CPET).

There are some processes in place for disposing of PET – namely mechanical and chemical recycling techniques – but most plastic around the world is still sent to landfills. PET can take hundreds of years to decompose and it’s non-biodegradable. This means it can continue to pollute the ecosystem for many years.

Making plastic requires lots of energy. Then, when plastics are thrown away, they cause environmental damage, including global warming, greenhouse gas emissions and damage to marine life.

On the other hand, there are some biodegradable plant-based plastics, such as polylactic acid (PLA), polybutylene succinate (PBS), polycaprolactone) (PCL) and polyhydroxyalkanotes (PHAs), which are friendlier to the environment than non-renewable polymers.

PLA polymers are produced from renewable resources and have the advantage of being recyclable and compostable. This makes PLA a much more environmentally friendly material than PET, PS and CPET. However, their long-term durability and stability are lower than their synthetic counterparts.

The new material

The new research has investigated the potential use of a biodegradable and renewable polymer, such as soy protein, to make a new material that could be an alternative to other plant-based plastics.

The researchers created a plant-based plastic and added nanoparticles – particles smaller than one millionth of a metre. This meant they could control the structure of the material to create flexible films, with a material that looks like spider silk on a molecular level. They’ve called it a “vegan spider silk”.

The team used various techniques, including scanning electron microscopy and transmission electron microscopy to study the structure of the film.

They analysed important properties, such as barrier properties and moisture absorption. They found the nanoparticles helped to increase the various properties – strength and long-term durability and stability – significantly.

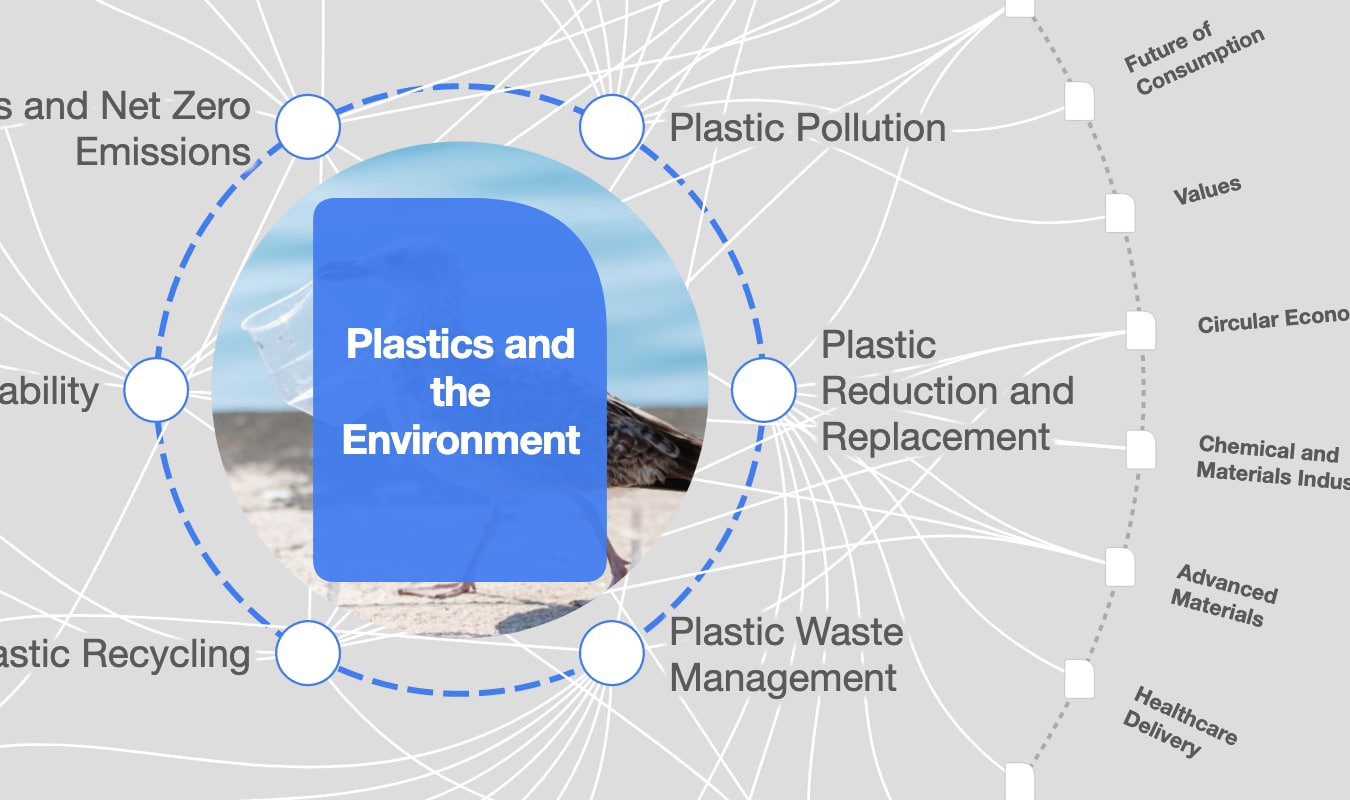

What is the World Economic Forum doing about plastic pollution?

By creating a plastic with a more environmentally friendly manufacturing process, made from sustainable materials itself, a significant amount of energy can be saved. This is one of the most exciting parts of this study.

This new material could help solve some of the problems that plastic pollution has caused to the environment – by introducing a material from renewable source with enhanced properties suitable for many engineering applications, including packaging.

The study could help to scale up the production of sustainable packaging materials, using natural resources and less energy consumption, while reducing the amount of plastic going into landfill.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Plastic Pollution

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Climate Action and Waste Reduction See all

Planet in focus: The technologies helping restore balance – and other news to watch in frontier tech

Jeremy Jurgens

November 13, 2025