The chemical industry can wean itself off fossil raw materials. Here's how

The chemical industry must examine its value chain in order to successfully decarbonize. Image: Reuters/Lisi Niesner

Listen to the article

- The chemical industry that underpins contemporary life is still heavily dependent on carbon-based raw materials.

- Recycled plastics, biomass and carbon capture provide viable ways of reducing chemical-industry emissions.

- The industry must establish new business models to hit the net-zero goal.

The chemical industry is a cornerstone of the global economy and is essential for all goods-manufacturing industrial sectors. It produces and enables many of the materials that propel modern development. Televisions and smartphones, for example, require the chemistry of light stabilizers and UV absorbers.

Without the chemical industry, crop yields would suffer due to the lack of pesticides and fertilizers. Food would perish faster without packaging. Heating costs would drastically increase without modern insulation materials. Electronic equipment would cease to exist without the specialty chemicals for semiconductors. And our personal care and hygiene would be much reduced without modern detergents.

The problem with fossil raw materials

After we finish using a product because it is depleted, outdated or defective, it ideally should go into recycling to keep the valuable carbon, which is a main component of most products, in the material loop as long as possible. This also avoids end-of-life incineration and release of CO2 into our atmosphere and its contribution to global warming. That valuable carbon most often originates from fossil raw material sources such as crude oil or natural gas, and is embedded in various molecular forms within our products.

The substitution of fossil raw materials with renewable biomass-based ones, such as agricultural or forestry waste residues, or with recycled materials such as plastics waste, is a viable and attractive method to reduce most emissions stemming from fossil-embedded carbon.

How can we substitute fossil raw materials?

A large part of the feedstock demand of the paper and pulp industry is already supplied by recycled paper products; however, behavioural change from each one of us is needed to succeed in this endeavour. In contrast to the paper industry, the chemical value chains around plastics are increasingly complex, and the products are often mixtures of multiple different plastic types. Nevertheless, recycling plastics and using a share of that to feed the chemical industry’s material demand could save up to 300 million tonnes of fossil-embedded greenhouse gas (GHG) emissions per year. Of course, other process-related emissions would also be potentially drastically reduced.

Compared to behavioural change in society, substituting fossil raw material sources with biomass requires a more substantial value-chain adaptation and technological innovation. The potential for GHG emissions abatement by using biomass-based production of ethylene and propylene, which are the most basic building blocks of the petrochemical value network, is enormous. However, biomass availability is limited on our planet; before we use any type of biomass for material or energetic purposes in the chemical industry, we must satisfy the demand for food. Only if some biomass is still left should bioenergy be targeted as a product. Since we cannot infinitely scale up biomass production due to biodiversity limitations, which we have already reached today in terms of land use, we must use the available biomass wisely.

Another highly attractive feedstock for the petrochemical value network is simple CO2. Via carbon capture and utilization, the chemical industry has the means to figuratively extract raw materials out of thin air. However, this process, called energy to methanol, is most efficient with highly concentrated streams of CO2, such as direct emissions from other industrial facilities. Taking it out of the air, as is being done in Iceland, is extremely inefficient and requires large quantities of energy and heavy investments.

What’s next?

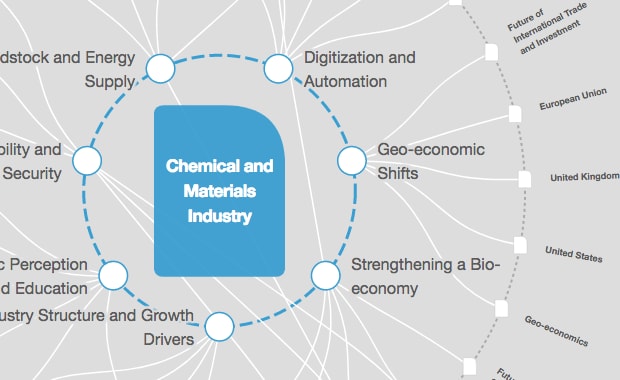

Together, these three feedstock types – recycled plastics waste, renewable biomass and CO2 – have the potential to reduce large amounts of global GHG emissions; however, they also require large amounts of green electricity, such as from wind or solar sources. Therefore, cross-industry action and change are needed for our society to succeed in this all-encompassing challenge to reach net zero by 2050.

How is the World Economic Forum facilitating the transition to clean energy?

New business models and novel collaborations among multiple parties from various value chains must be developed and established to succeed in this goal. Change is required from all of us: Mindsets and established business models in the industry must change, society’s behaviour must change, policies and regulations must change, funding opportunities must be created. With a shared ambition to put the chemical industry on a path to net-zero emissions by 2050, major chemical sector companies and the World Economic Forum have established the Low Carbon Emitting Technologies (LCET) initiative. This aims at accelerating the development and upscaling of low-carbon emitting technologies through a collaborative innovation approach resulting in the creation of lighthouse projects in key value chains.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Chemical and Advanced Materials

Related topics:

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.