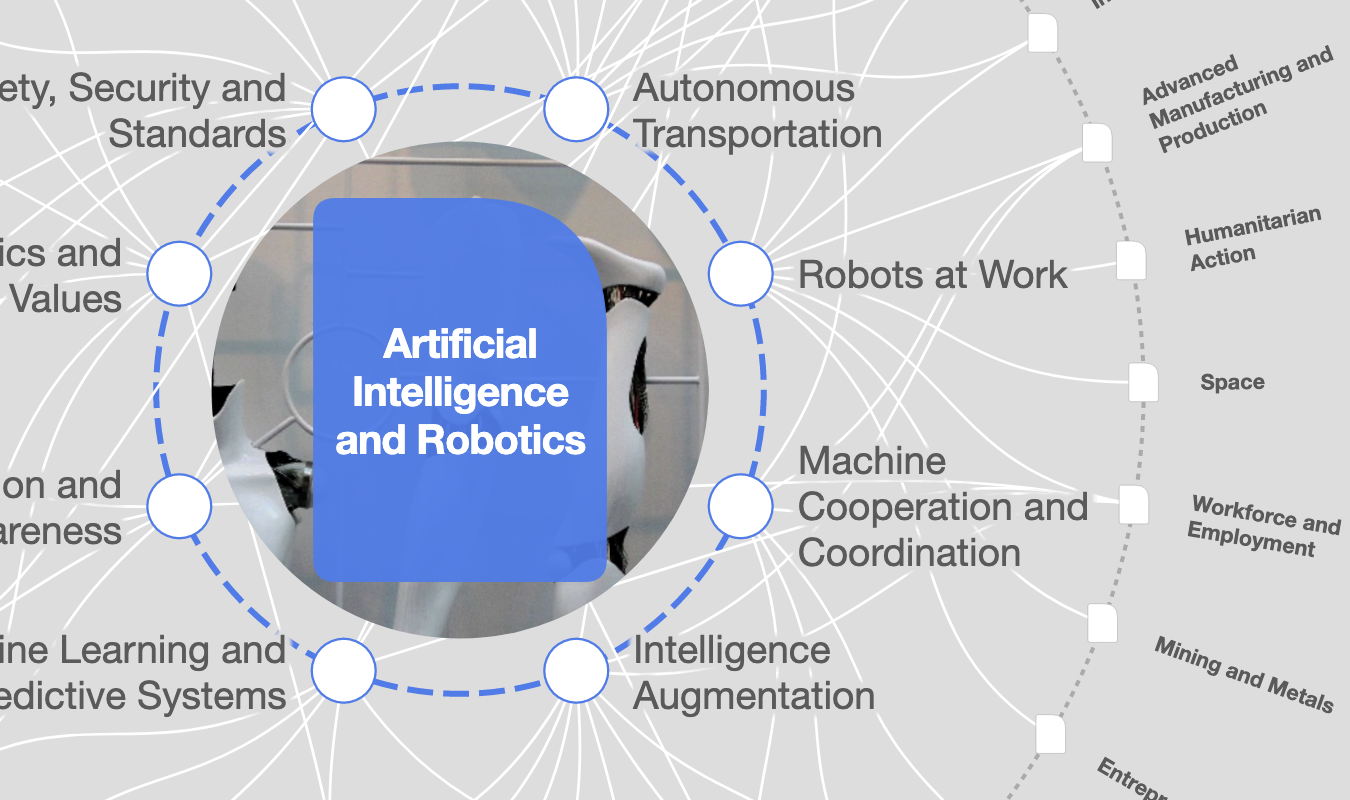

Beyond the status quo: How generative AI will transform industrial operations

Generative AI can help manufacturers unlock their full potential. Image: Getty Images/iStockphoto

Kyriakos Triantafyllidis

Head of Growth and Strategy, Centre for Advanced Manufacturing and Supply Chains, World Economic ForumListen to the article

- Manufacturers are increasingly employing cutting-edge technologies powered by artificial intelligence to address challenges like supply chain disruption.

- Technological breakthroughs such as generative AI look set to enable industrial companies to open up even more of their potential.

- The World Economic Forum and partners, including BCG, invite manufacturers to join the AI-powered Industrial Operations to collectively accelerate the transformation towards AI-powered industrial operations.

Recent challenges such as supply disruptions, price volatility, talent shortages and the sustainability imperative, are increasing the complexity of industrial operations. To address these challenges and unlock the next wave of value, leading manufacturers are employing cutting-edge manufacturing technologies powered by artificial intelligence (AI).

These technologies present industrial companies with fresh avenues to navigate their way through turbulence and offer opportunities to substantially boost their operational performance.

At the same time, technological breakthroughs continue to emerge and recent developments, such as in generative AI, open up even more potential.

What is AMNC, the World Economic Forum's meeting in China?

While some leading manufacturing companies have already successfully implemented a variety of AI applications, many others are only at the beginning of their AI journey.

To shed light on where manufacturers stand with AI today, Boston Consulting Group (BCG) analysed insights from almost 1,800 manufacturing executives worldwide in their 2023 study AI-Powered Industrial Operations.

For manufacturers just starting their AI journey, these insights offer a window into the potential impact of AI and the typical implementation challenges.

Here is what the results reveal:

AI is penetrating industrial operations worldwide

Simply put, manufacturing executives are very optimistic about AI. A striking 89% of executives see AI as essential to their operations and plan to incorporate it into their production.

This commitment reflects a broader understanding of AI's promise – roughly two-thirds (64%) of executives perceive a high potential for AI applications to drive production efficiency improvements.

Beyond being a means for productivity, many executives also view AI as promoting substantial opportunities for sustainability (53%), production flexibility (52%), and workforce support (47%).

And this isn't just talk either – progress is already under way as 68% of executives have already fully implemented at least one AI use case.

Given the wide array of AI applications within industrial operations, many executives are looking to understand what the most promising use cases and the most value-adding ones for their context are.

While there is no universal answer, applying AI in quality control – such as computer vision-based applications – is the most mature and relevant use case today.

One in four of the surveyed executives report using AI in their quality control processes in some way. But other AI use cases are gaining traction as well, such as robotics and production automation, production alert systems and inventory optimization. Each of these is used already by about one in five respondents.

Taking a look at different industries, electronics and technology equipment, with 83% AI adoption, leads the way by a significant margin, followed by energy at 72% and process industry at 68%.

Scaling AI in production is a universal challenge

Early adopters have confirmed the potential of AI in the industrial context, realizing, on average, 14% savings on addressed manufacturing costs to date.

However, many companies struggle with successful AI implementation, especially when scaling AI within their production network. Only 16% of respondents have achieved their AI-related targets, and nearly all respondents (98%) cited scaling AI as particularly challenging.

The issues highlighted in this context can be grouped into two categories of enablers – organizational and technological.

- 92% of respondents stated that insufficient organizational foundations hinder the scaling of AI and obstruct them from achieving their AI-related goals. Within this category, a scarcity of digital skills and capabilities (39%) and the absence of an AI strategy and roadmap (33%) are the predominant challenges.

- 88% of respondents mentioned a deficient technology foundation as a significant impediment. Inadequate data processing and data visualization infrastructure are the top challenges, each cited by 34% of respondents.

How generative AI transforms industrial operations

While industrial companies seek to overcome the obstacles to capturing AI’s full potential, the technology continues to evolve. Innovations, such as large language models and their application in the context of generative AI, have revealed new opportunities. How does this advanced technology promise to transform industrial operations?

Three main types of generative AI applications in the manufacturing environment:

Providing information support: In the industrial context, well-established generative AI models and tools operating like ChatGPT can be used to automatically generate text to support operations. Applications include, for example, supporting equipment maintenance by generating maintenance instructions for remote support or creating standard operating procedures.

Converting information to output: Generative AI applications able to convert text to code or images allow companies to accelerate manufacturing related processes for instance in process automation by creation of programme code based on text input.

Enhancing robotics: Generative AI in robotics holds the promise of enabling robots to automatically act on, for example, voice commands without the need for task-specific training and regular retraining. This facilitates new application areas for robotics in industrial operations, such as automated material or tool supply, which would allow companies to increase production efficiency while reducing engineering costs and ramp-up times.

Although most of these applications are in the early development phase and have yet to be widely implemented, leading manufacturing companies are seeking to understand how they can use generative AI in operations, what possibilities it might unlock and how to implement it.

However, as with the introduction of AI in general, it is imperative to overcome the organizational and technological challenges outlined above to benefit from these developments. Without a comprehensive implementation approach as well as solid organizational and technological foundations, companies will struggle to move beyond piloting use cases and to realize AI's full potential in industrial operations.

A joint initiative to support manufacturers

To support manufacturers on their journey towards capturing the full potential of AI, the World Economic Forum in collaboration with BCG, Tuv Sud, and the Centre for the Fourth Industrial Revolution in Türkiye has launched the global initiative AI-powered Industrial Operations.

How is the World Economic Forum contributing to build resilient supply chains?

The initiative seeks to raise awareness about the potential of future-oriented AI applications, co-develop with its community an educational guidebook on implementing and scaling AI in industrial operations, and deep dive into the importance of AI quality in ensuring successful sustainable outcomes. It is also incubating collaborative pilots on new AI applications.

The World Economic Forum invites manufacturing companies to join this initiative to collectively accelerate the transformation towards AI-powered industrial operations.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Advanced Manufacturing and Supply Chains

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Forum in FocusSee all

Gayle Markovitz

October 29, 2025