Cement and concrete: Building a cluster-based innovation ecosystem

The cement and concrete sector is fundamental to global growth — but its emissions must be reduced. Image: Unsplash/Denis Lau

Andreea Visan

Specialist, Transitioning Industrial Clusters, Programming and Communications, World Economic Forum- Demand for cement is expected to grow by 14% from 2020 to 2030, and another 22% by 2050.

- Cement and concrete are produced and used locally, making local sector transition strategies vital.

- Industrial clusters offer an ideal transition ecosystem, with the cement and concrete industry's innovative practices offering an example to the wider industry.

Concrete is the most widely used commodity on earth after water, and is the backbone of urbanization. But we take concrete and its key ingredient cement for granted, thinking little of its ubiquitous use in most construction, be it housing, offices or infrastructure.

The cement and concrete sector’s emissions make up 7%-8% of all human-made CO2 emissions. In an increasingly sustainability-focused world, the traditional way of making concrete and cement needs to change.

With a 2050 goal of net-zero, the cement and concrete industry is working with partners across sectors to transform. The Mission Possible Partnership Global Project Tracker suggests that if 45 low-emission cement plants come online by 2030, the industry will remain on track to achieve below the 1.5 °C threshold with its greenhouse gas (GHG) emissions.

There is no one-size-fits-all solution. The transition of the cement and concrete industry implies multiple levers are required to reach net-zero, from increasing concrete efficiency in planning and construction to switching to sustainable energy sources and reducing the clinker content in cement.

To achieve this level of transformation, cement and concrete companies need to develop holistic strategies within the broader context of the heavy industry and energy transition. They also need to collaborate with all stakeholders in the value chain and companies in the same industrial area.

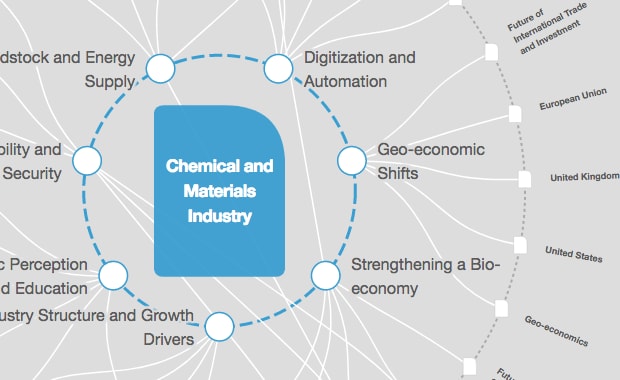

The Transitioning Industrial Clusters initiative convened by the World Economic Forum supports industrial areas to unlock collaboration between co-located companies and public institutions at an industrial cluster level, facilitating the industry and energy transition.

The advantages of a highly localized market

Given that cement and concrete are produced and used locally — concrete within 50km and cement within 250km of its final use — the solutions for the sector’s transition must be tailored to regional conditions.

Demand for cement is expected to grow by 14% from 2020 to 2030, and another 22% by 2050. This is largely driven by the need to provide housing and key infrastructure in the world’s fastest developing areas, so identifying the right solutions in those regions is crucial.

In the Middle East and North Africa, Consolidated Contractors Company (CCC), a member of the First Movers Coalition’s (FMC) Cement & Concrete sector, is committed to advancing sustainable construction practices in the region. By integrating fossil fuel-based supplementary cementitious materials (SCMs) to the concrete mix, the company can reduce emissions associated with the cement production process.

CCC is spearheading green concrete initiatives throughout seven key projects located in Qatar and Saudi Arabia. These projects are scheduled to take place from 2024 to 2025, and involve integrating 70% green concrete in the total production: an important milestone on the road to meeting the FMC’s ambitious low-emissions thresholds.

Other regions and countries are adopting a more focused and integrated approach, showcasing how local markets and co-located companies within industrial clusters can collaborate to support the sector’s transition. One of them is Thailand.

Pursuing an industrial cluster approach

Thailand’s Saraburi province produces more than 80% of the country’s cement. A group of stakeholders, supported by the Thai Cement Manufacturers Association (TCMA), has created the Saraburi Sandbox, a cluster-based innovation ecosystem for a low-carbon city. It is the newest member of the Transitioning Industrial Clusters community. The cluster is committed to becoming net-zero by 2050 and enhancing the quality of life in Saraburi province.

This case highlights how local authorities can leverage one industry’s ambition to transition to build a holistic strategy for both the region and the city. This undertaking involves seven government ministries and 23 organizations, including the Thai Cement Manufacturers Association (TCMA) and the Federation of Thai Industries (FTI) Saraburi. The main efforts include research and development, advancing new technologies, and streamlining funding into pilot projects. In pursuing these, the project aligns with the country’s wider Nationally Determined Contribution (NDC) commitments.

One of the key results is Mission 2023, a TCMA-led initiative with collaboration from 31 government, professional, industry and academic organizations, who are supporting six ministries. This aims to accelerate the transition of all construction projects nationwide using Hydraulic Cement by 2023, making a major contribution to CO2 emission reduction in the Industrial Processes and Product Use (IPPU) sector of Thailand’s NDC roadmap.

Collaborating beyond local clusters

Some projects leverage the industrial cluster to build partnerships with other sectors.

Holcim’s GO4ZERO CCUS project in Obourg, Belgium, is working closely with companies that are normally outside the cement ecosystem, and in doing so, developing a new and large-scale industrial value chain to reduce emissions. The project’s goal is to co-create a new industrial value chain that includes industrial gas and infrastructure companies.

The project will deploy a new air-oxyfuel switchable kiln and cryogenic carbon purification technology. Through links to local transport, terminals and shipping infrastructure, CO2 from the production process will ultimately be sequestered under the North Sea.

This is a huge undertaking that requires indispensable collaboration between the public and private sectors, spanning a spectrum of activities ranging from deploying first of a kind technologies to securing financing and obtaining the necessary permits.

Cement and concrete companies need to leverage multi-stakeholder collaborations within industrial clusters and throughout sectors to achieve net-zero. As the industry moves towards this 2050 goal, its approach represents a shift towards more sustainable production practices and signals a broader commitment to collaboration and innovation in one of the world's most essential sectors.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Transitioning Industrial Clusters

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Energy TransitionSee all

Roberto Bocca

November 17, 2025